Our Goal

Pro Line Machining, LLC has the highest of standards. Managing high-quality, cost-effective machine and mine equipment repair services such as machining, welding, mechanics, and all other repair and maintenance projects safely and on schedule by employing and supporting motivated, flexible, and focused teams. We value the importance of our relationships and will continue to remain fair and true in our dealings with all employees, clients, vendors, and partners. Our clients count on our dependability, our drive, and our integrity. We take great pride in our accomplishments and build on them every day.

Quality Services 24/7

Quality comes from knowing what you’re doing and caring that it’s done right. At Pro Line Machining the simple fact is we build better, we build quality, no exceptions.

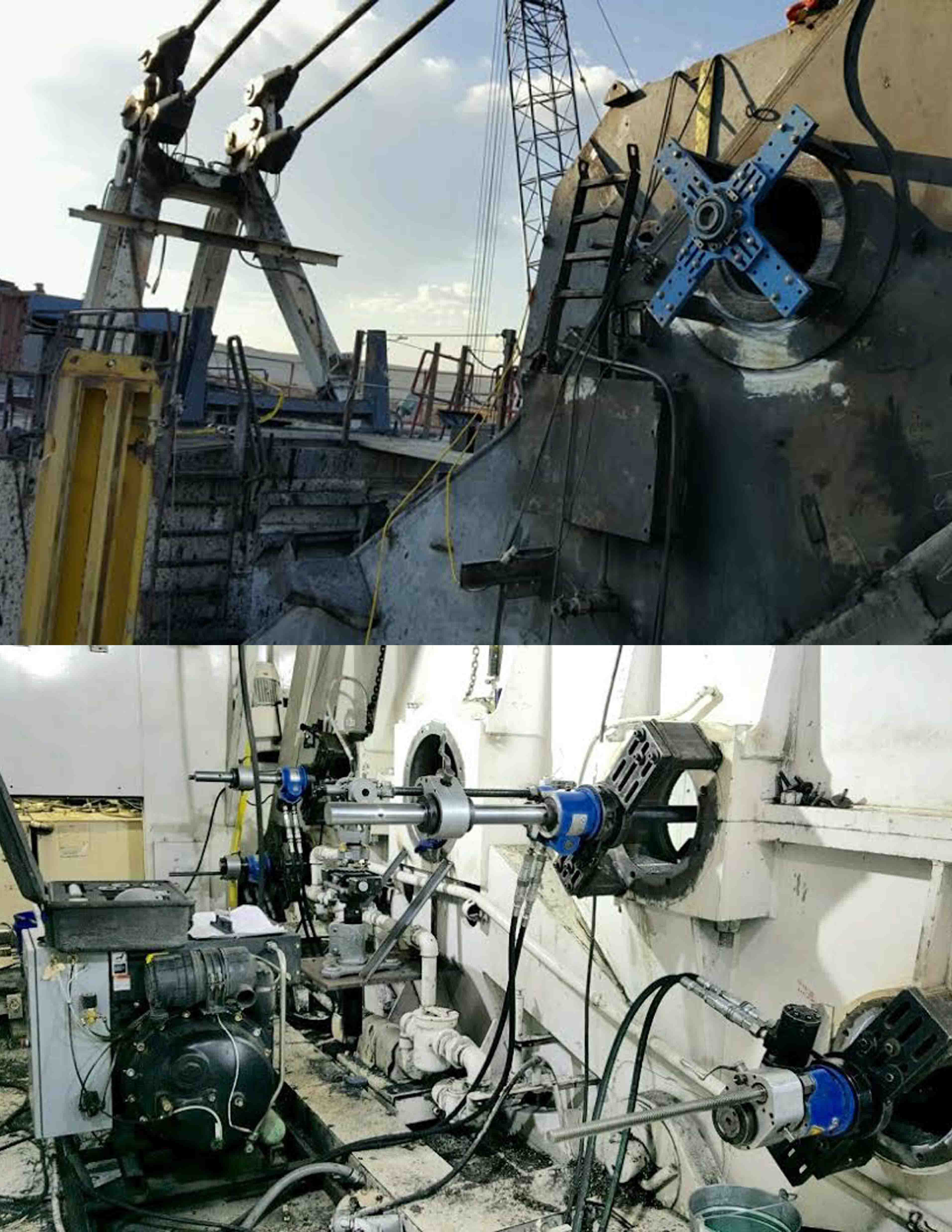

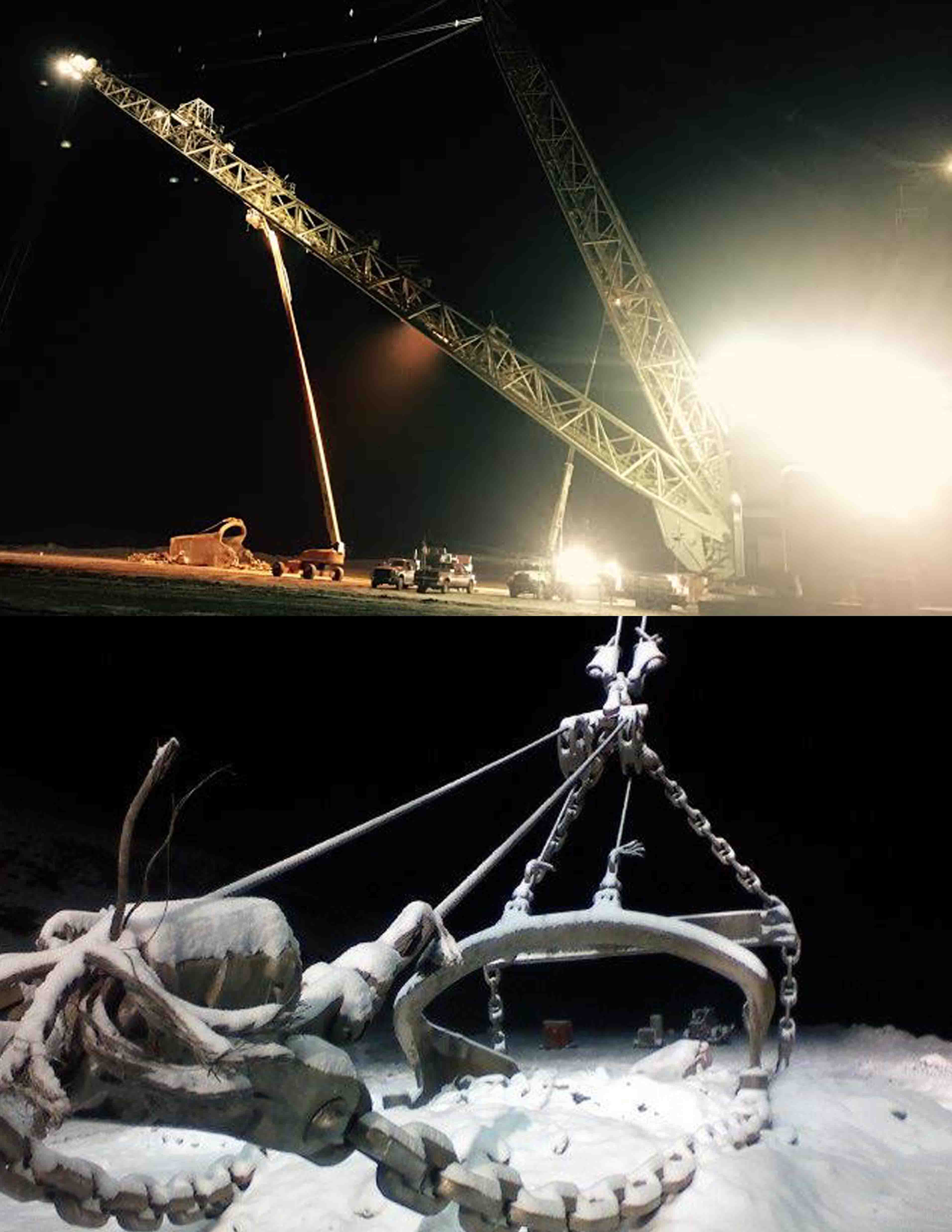

With Pro Line Machining, you get the best of the best. Whether we’re doing a complete undercarriage replacement on a mining shovel, to over hauling mud pumps on ig locations, or performing routine inspections and maintenance on a dragline, you can count on our field employees whom have experience in what you need to have done, all the proper certifications, protocols for insuring correct completion, and the proper equipment for the job.

Field Repair Services

Keeping in mind safety, first and always, as our master tradespeople provide complete field machining, rigging, welding and mechanical services for heavy equipment fleets:

Rush breakdown repairs

Failure analysis & troubleshooting

Full machine audits & inspections

Scheduled outages

Machine upgrades, retrofits, rebuilds and overhauls

Structural evaluation, rebuilds and configuration changes

Transmission / gearbox rebuilds

Teardowns & relocations

Blast hole drills – Drill mass straightening & complete overhauls

Equipment customization

Dragline boom welding and repairs

Massive booms and machine structures

Proline Machining also has advanced capabilities for manufacturing, rebuilding and upgrading machine structures of all sizes. Our fabrication expertise range from booms and shovel undercarriage designs to custom component modifications and whole machine upgrades.

Machining

Our machine assembly processes utilize our expertise in planning and project management, along with strict adherence to quality processes and standards, while assembling new machines safely, on time and on budget, topped off by our flawless start-up operations.

Our rebuild process applies unparalleled experience, service capabilities, facilities, and personnel to deliver like-new performance at a cost significantly less than purchasing a new element.

We ensure that required production enhancing technology upgrades are correctly installed and rigorously tested.

Integrate a full range of technical expertise and support services.

Provide accurate assessments of machine health by drawing on a database of nationwide practical experience

Handle the entire rebuild process, including auditing, diagnostics, cost estimating, parts procurement, planning, disassembly, repair and replacement, testing, training, and start up.

Welding

We have trained welders experienced in aluminum tig to standard 8000Ni2 dual shield.

Our welding setups are fully equipped for portable welding to any location in the field or anywhere welding needs arise. We operate 6 generator powered DC 600 welders or diesel powered airpack trailer mounted welders.

A large variety field expertise including crack repair, building up bores, boom welding, buckets, dozer blades, dragline buckets, dippers, loaders, loader bucket rebuilds, boom, stick and bucket repairs for hydraulic shovels and track hoes, entire machine repairs and upgrades.

Training

confined space trained, MSHA Certified, At Heights Training, Rigging and Crane Training, Equipment Operating, Scaffolding Training, in-house CWI Welder Training and Certification and More!

CWI / NDT Services

NDT Services

- UT Shear Wave Inspections

- UT Longitudinal Inspections

- Phase Array Inspections

- Magnetic Particle Inspections

- Dry / Wet Fluorescent

- Die Penetrant Inspections

- ASNT Level III UT, PT and RT Services

CWI Services

- Welder Testing & Training

- Welder Certification

- QA/QC Inspections & Procedures

- Welder Qualification Tests

- Visual Inspections

Mechanics

At Pro Line Machining we know the mining industry relies heavily on a well trained crew of mechanics to keep their equipment running. You can count on us to meet your mechanical needs. From electronic shovels, draglines, to blast hole drills.

Equipment Rental

With a large range of portable equipment, our professionals have all the tools to get the job done.

6 Pack Welder DC 600

4 Pack Welder V350 Pro

500 KW Generator

Portable FF 8200 Mill

JLG Telehandler 10,000 lb

T870 Skid Steer 10,000 lb

3.5″ Stub Shafts & Mounting Plates

Taylor Forklift 36,000 lb

Brunson 76-RH Transit

Airless Paint Sprayer

6 – 500 ton Rams

2.25″ Portable Machining Bar

3.5″ Portable Machining Bar

Shop Equipment & Capabilities

This section is under construction. Please keep checking back for updates. Thank you.

LATHES

Hercules Lathe 42″x120″

Lodge and Shipley Lathe 22″x96″

MILLS

Kent Mill 12″ 48″ bed

Lucas Mill 5″ spindle with 12’ travel

Portable Radial Climax Mill min 5’, max 12’ diameter

DRILLS

Several lamina drills

Archdale drill press 3″ with 60″ swing and 60″ bed clearance

MACHINERY

2-40 ton bridge cranes with 2-20 ton trolleys each

6800 lb shop forklift

10k lb telehandler

36k lb forklift

10k lb skid steer

PORTABLE MACHINING EQUIPMENT

3.5″ portable bore equipment hydraulic

2.25″ portable bore equipment both electric and hydraulic

Brunsun bore scope

WELDING MACHINES

6-652 480v welding machines

3-450 xmt welding machines

portable 6 pack 650 welding machines

several 252 hardwire machines

20 plus LN-25’s

SHOP TOOLS

Oliver Drill Bit Sharpener up to 0.25 to 3″

Sucker Fans

Pipe Bevellers

Track Torches

Plasma Cutters

Hydraulic Pumps to run boring equipment, rams, drills, ect.

Airless Paint Sprayers

LIFTING EQUIPMENT

Varies porta-powers and rams

6- 500 ton rams

STRESS RELEIVING

5- stress tech systems with ceramics and leads